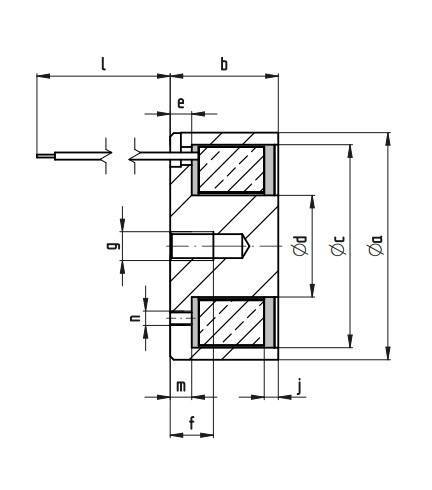

Holding electromagnet

Code: E919001 E919002 E919003 E919004 E919005 E919006 E919007 E919008 E919009 Choose variantProduct detailed description

|

Holding electromagnets consist of a coil and a metal core. An electric current flowing through the coil winding creates a magnetic field in the core of the holding electromagnet. This magnetic field is used for holding objects, Holding electromagnets have great holding power - electromagnets with a diameter of 25 mm can hold up to 14 kg! Using more electromagnets makes achieving a higher holding force / carrying capacity possible. Another advantage of a holding magnet is the fact that it does not magnetize and manipulate when at rest. That is why, they are completely safe and easy to handle (compared to permanent magnets). |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The use of a holding electromagnet can have many advantages for industrial processes, automation, and safeguarding systems. Its use improves work safety, speeds up processes, and increases work efficiency. They can often be found in manipulators or grippers. The most common use of holding electromagnets:

However, there are factors negatively affecting the holding power. These are undesirable material impurities in the electromagnet or in the object (such as carbon, chromium, nickel, manganese, molybdenum, copper, etc., reducing the holding force). Furthermore, there is the roughness of the holding surfaces (the greater the roughness, the lower the holding force) and the air gap (the larger the gap, the lower the holding force). None of the standard holding magnets is suitable for you? Please contact us, we shall design a tailor-made solution for you. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Be the first who will post an article to this item!